Plan your production efficiently

Optimize your production efficiency with intelligent planning strategies to ensure a smooth and effective manufacturing process. Optimal OEE for all machines.

Transparency and optimization of production ensure optimal use of resources.

Detect machine downtime immediately and take proactive countermeasures to minimize production times.

Avoid obsolete stocks in advance through forward-looking planning.

Prioritization to the essentials and automated risk detection enable quick decisions.

1

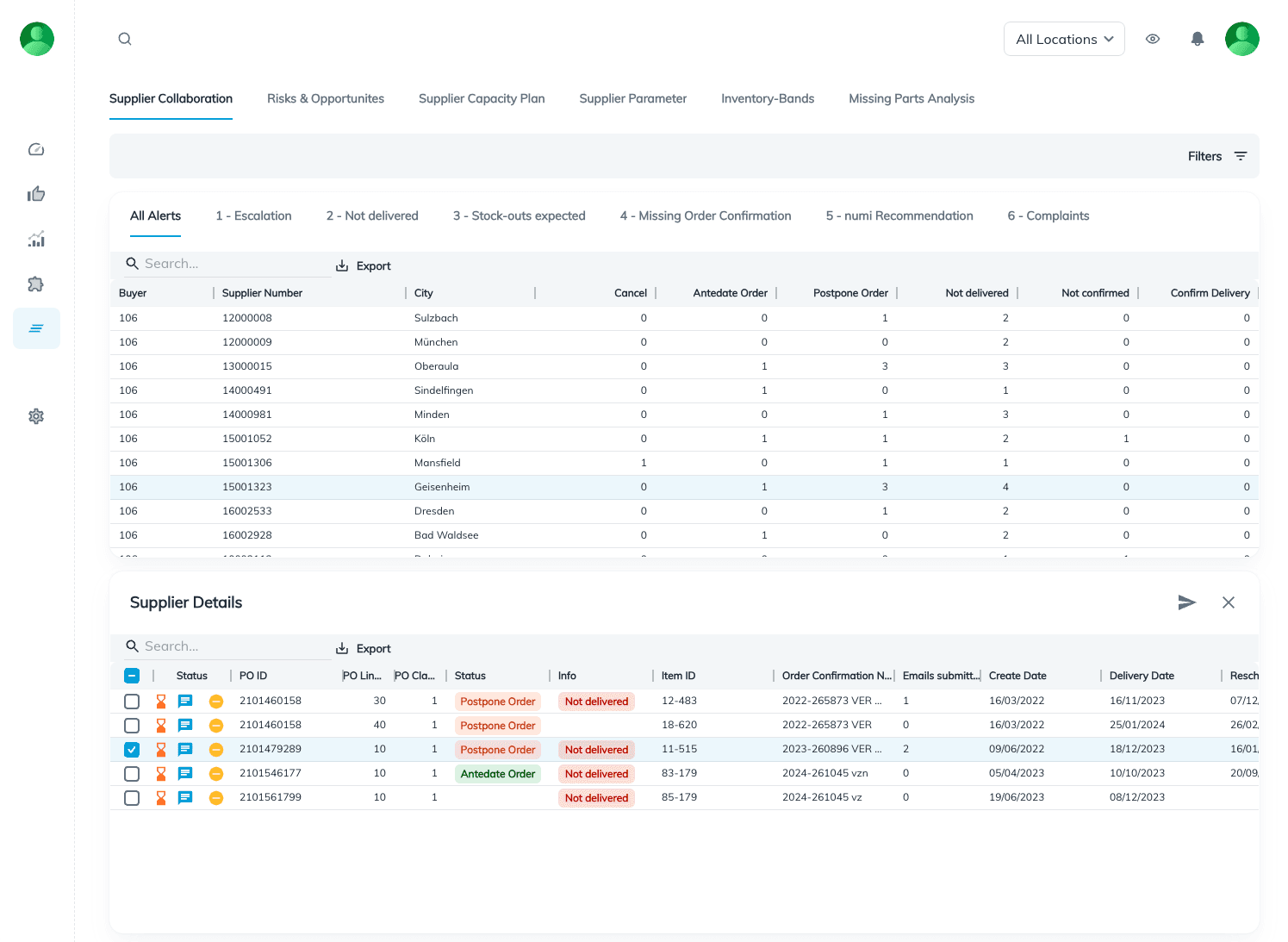

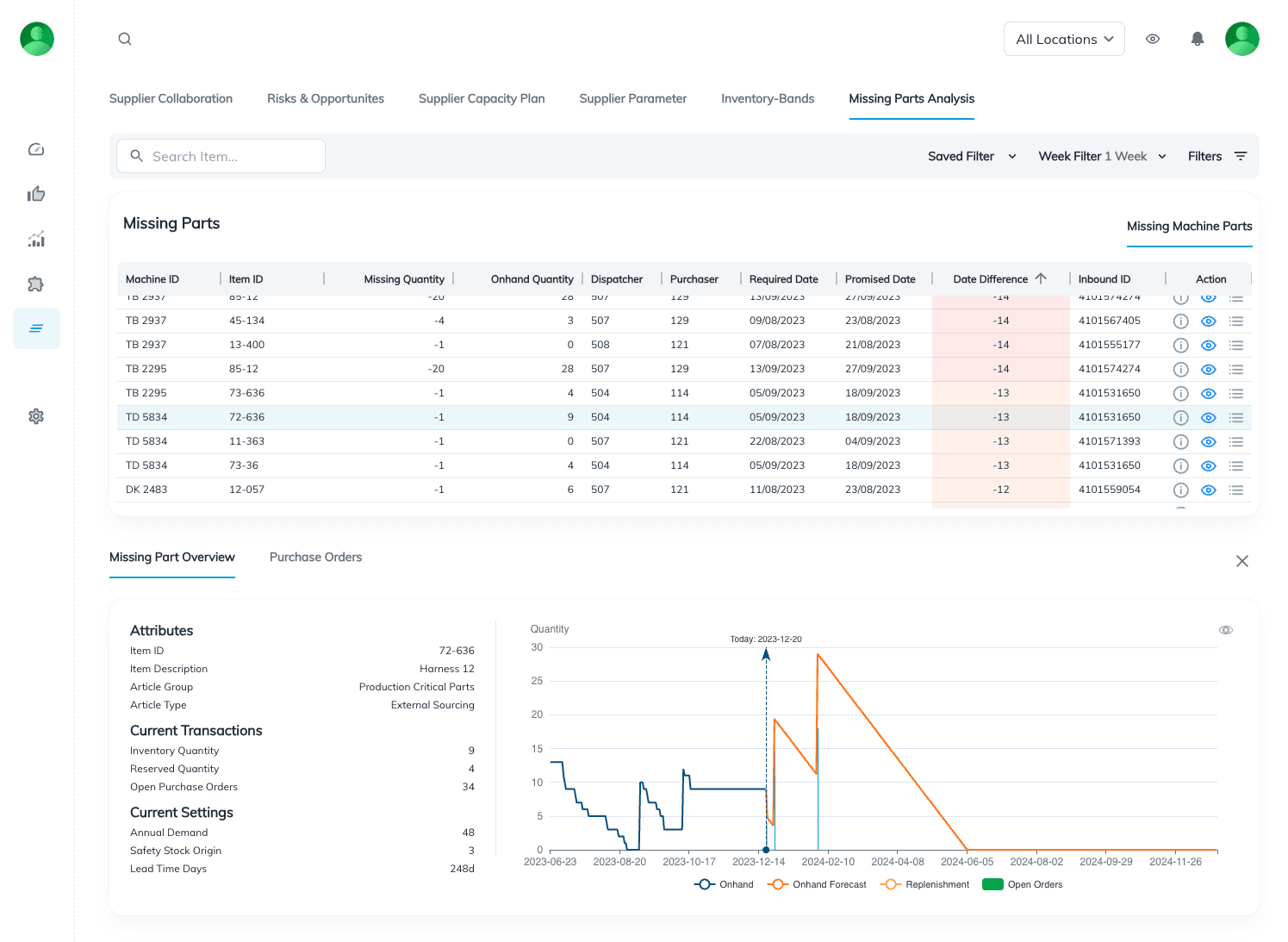

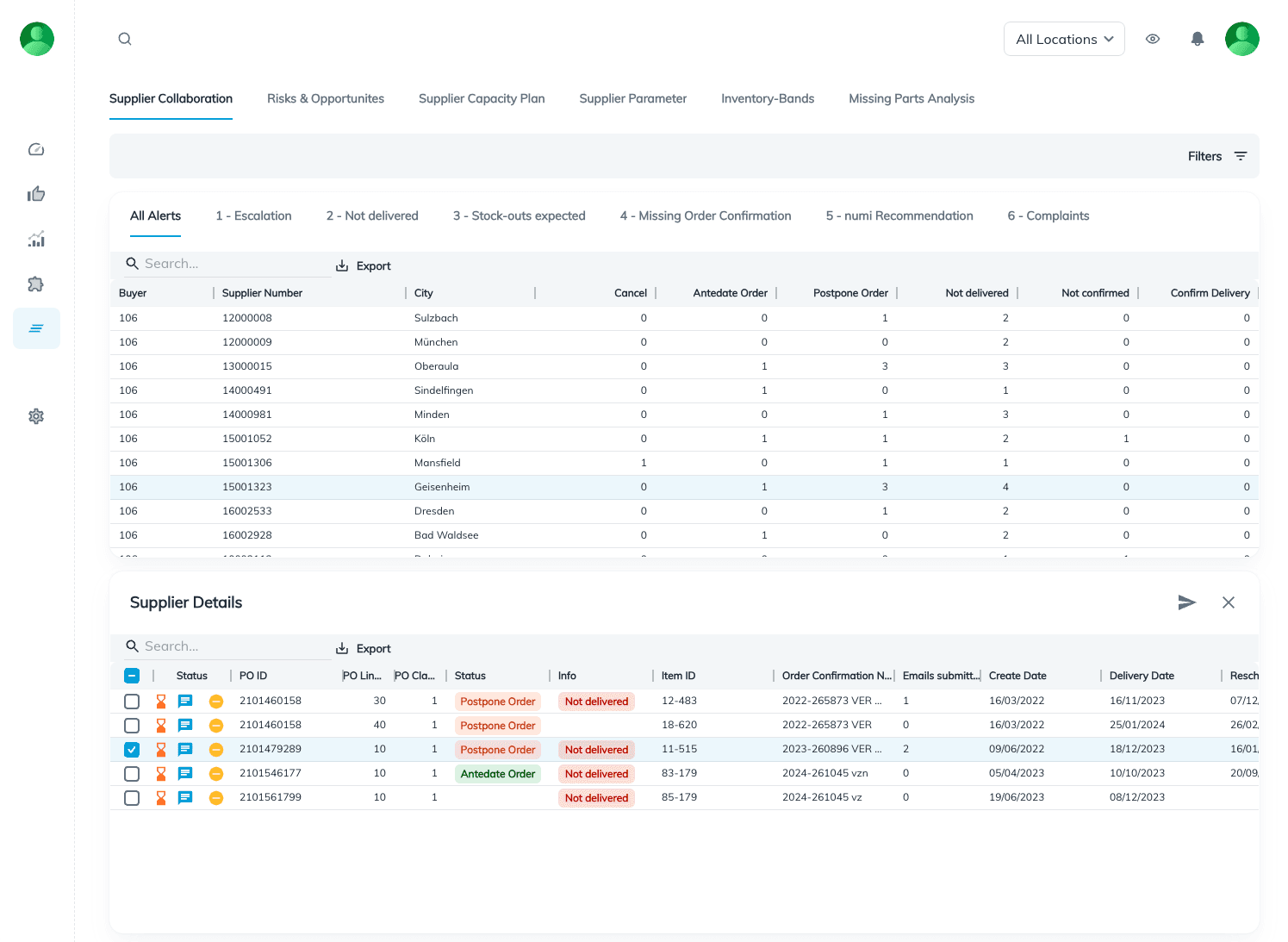

Examine Production Plan

Missing Parts:

Get alerts for production orders with missing raw materials and components.

Excess Orders:

Avoid unnecessary production orders and excess inventories.

Production Processes:

Get tailored algorithms to enhance accuracy.

2

Validate Production Recommendations

Production Order Creation:

Create production orders bases on customer orders or forecasts.

Integrate Constraints:

Select constraints like due dates, precedences or resource capacities.

Optimization Goal:

Tell numi your goals - Minimize setup times, minimize customer order delays or combined target functions.

3

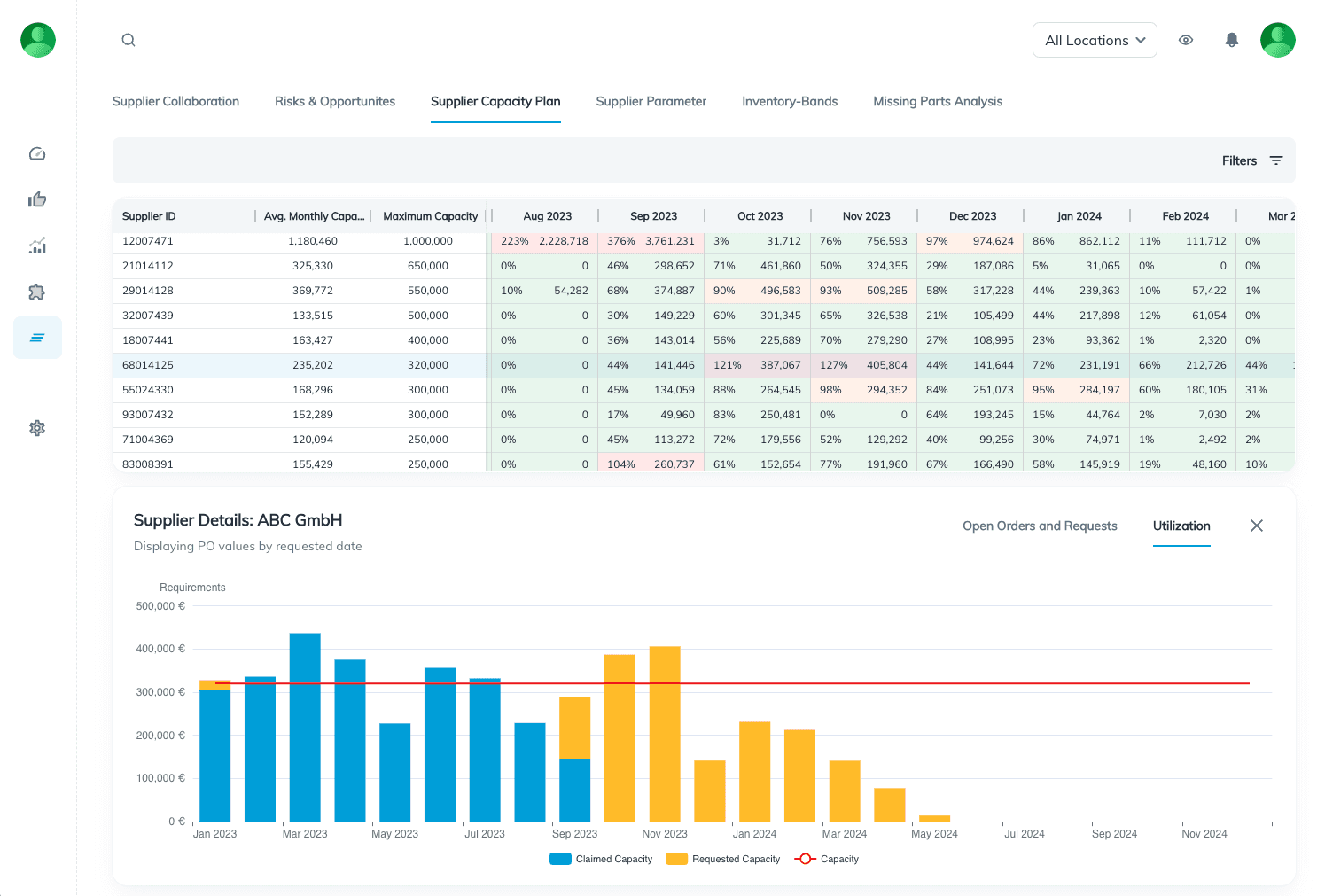

Evaluate Production Capacity Plans

Visualize Orders:

Aggregate orders on any desired resource level.

Capacity Constraints:

Map capacity constraints against production resource requirements.

Inventory Development:

Visualize inventory predictions for raw materials, components and finished goods.