Optimize your Operational Purchasing

Use numi's Replenishment App to make your purchasing activities as efficient as possible. Put the right materials in your warehouse at the right time with the most cost-efficient purchase order transactions. Let's strive for automated replenishment decisions.

Cost-optimized order quantities and sources lead to considerable savings potential in purchasing.

Accurate and system-generated decision recommendations reduce unnecessary manual activities.

Our predictive replenishment logic avoids future overstocks and indicates unnecessary orders.

Replenishment recommendations can be validated within seconds or even fully automated.

1

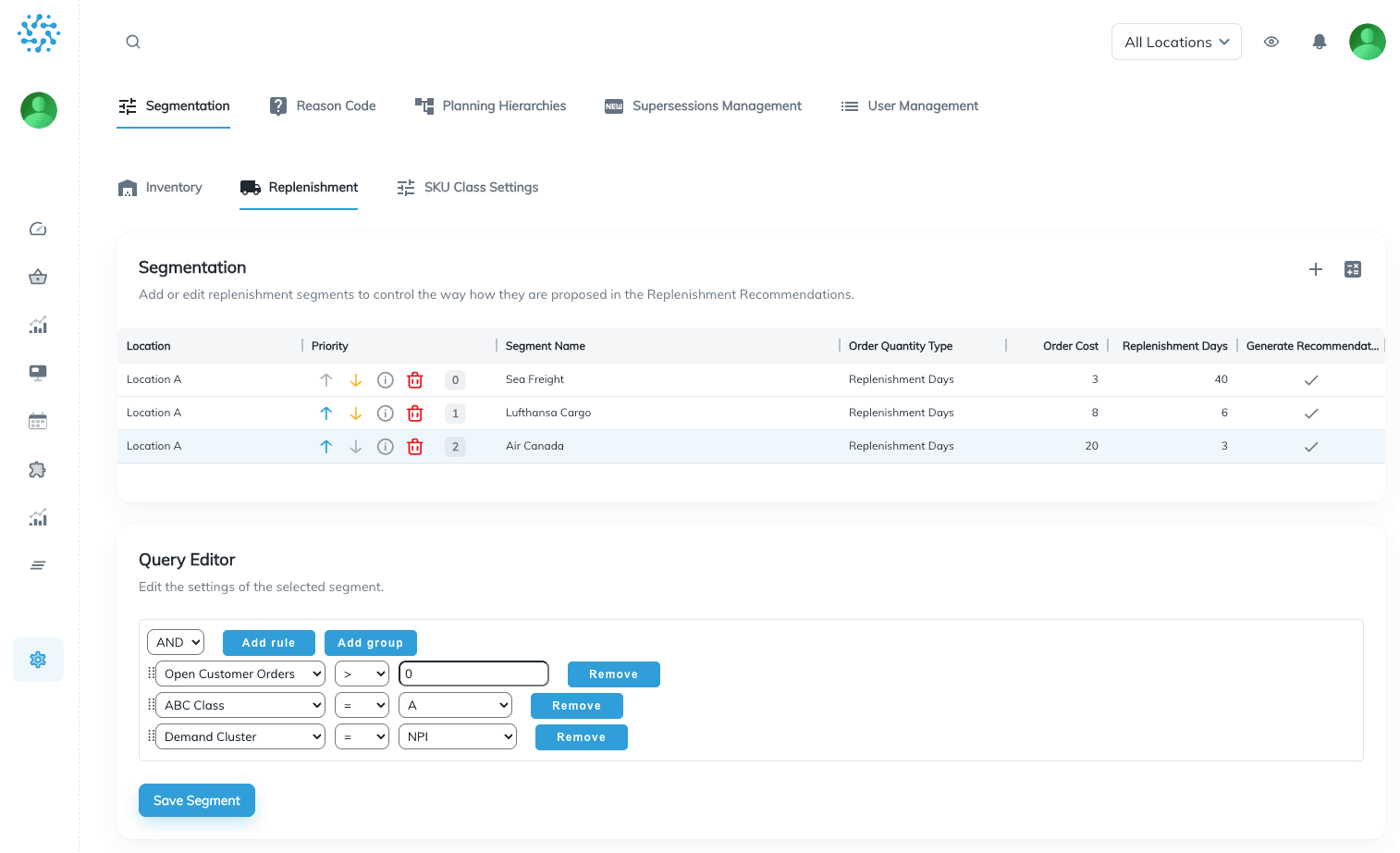

Replenishment Strategy

Optimal Tradeoffs:

Balance between cost efficiency and high availability to optimize your margin

Inventory Classification:

Compute inventory classes to define strategic goals.

Replenishment Segments:

Establish replenishment segments for effective and targeted replenishments.

2

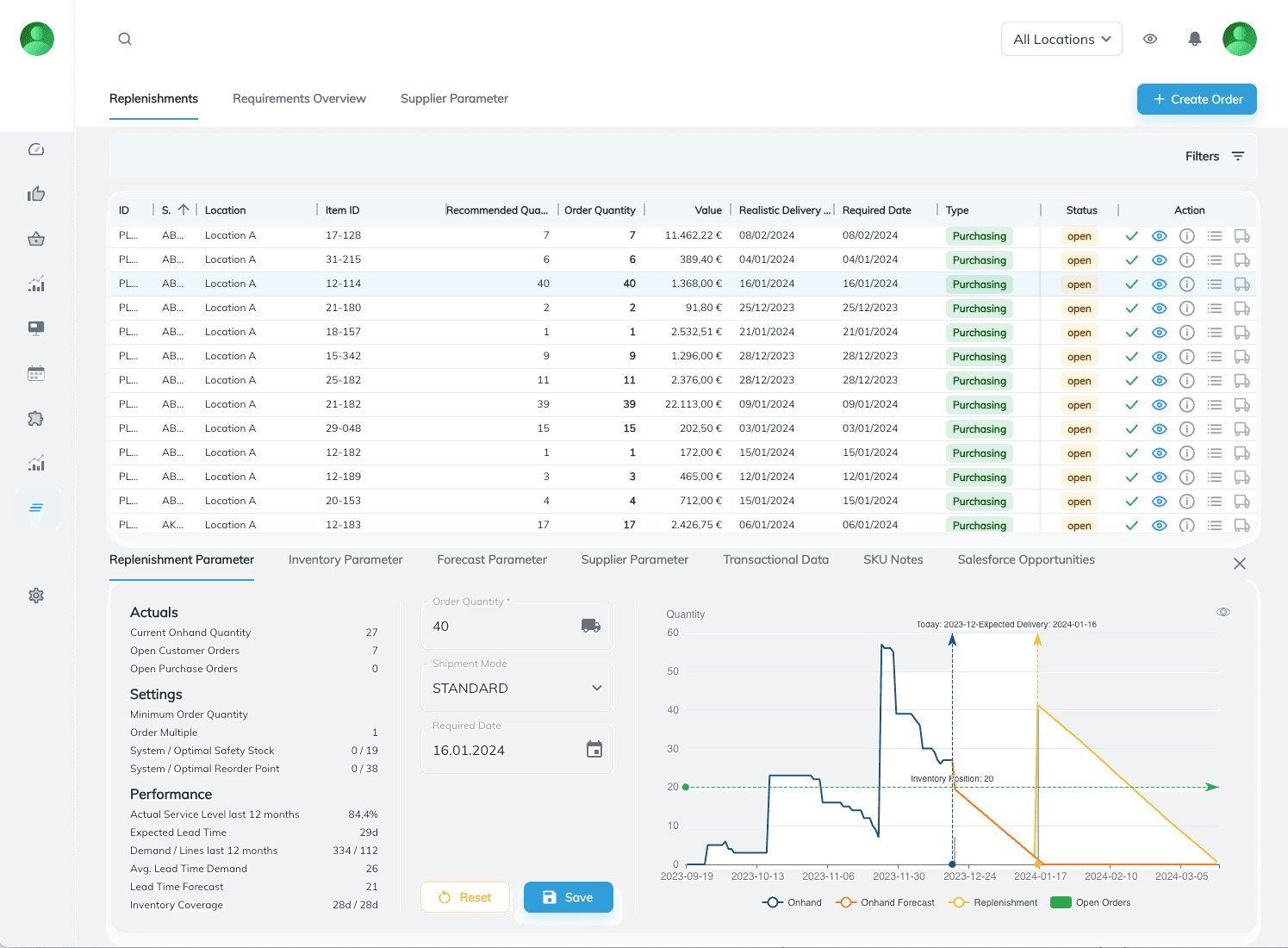

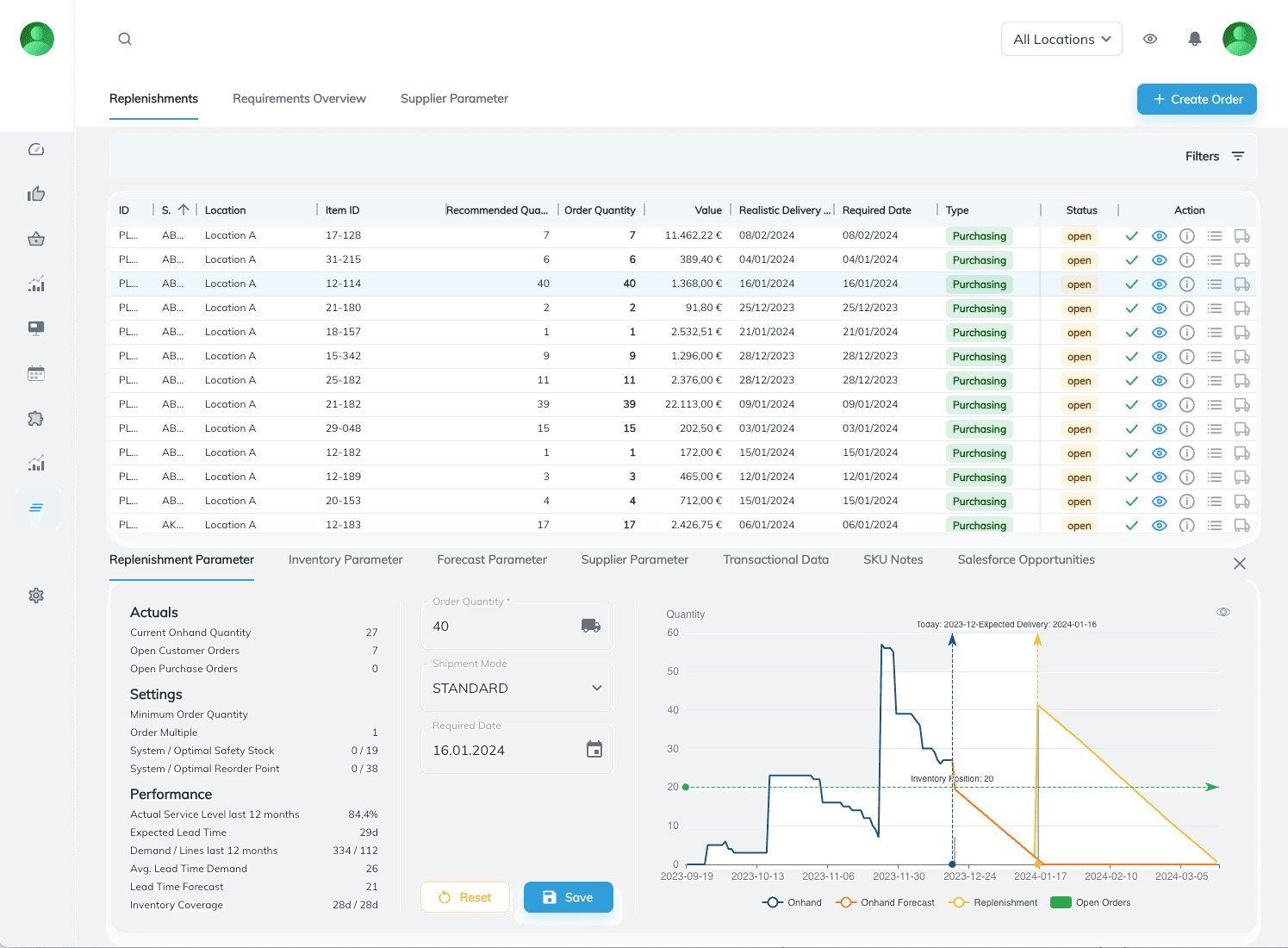

Replenishment Recommendations

Purchase Order Proposals:

Create purchase orders with cost optimized quantities at the right time

Network Optimization:

Fine-tune multi-echelon network stocks and stock transfer proposals at each node in your network.

Optimal Sourcing:

Choose the best sourcing options with a keen eye on cost-effectiveness.

3

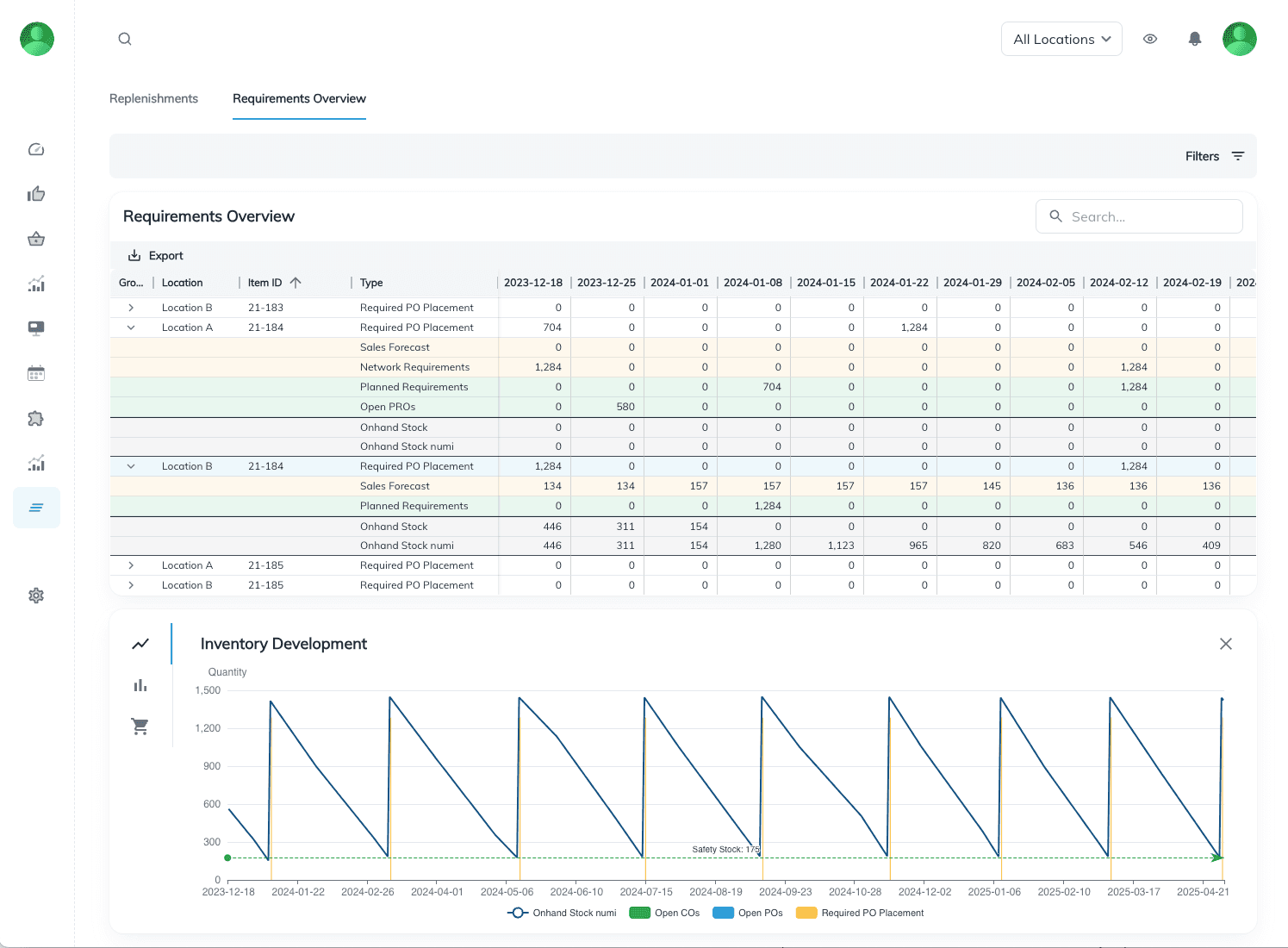

Copmonent & Raw Material Requirements

Bill-of-Material Breakdown:

Explode multiple Bill-of-Material levels and sales bundles.

Network Analysis:

Assess requirements at each node of your production and distribution network.

Net Requirements Planning:

Develop a dynamic and forward-looking supply plan and share it with internal and external stakeholders.